The co-extrusion produces a preform with optimum diameter stability and core/clad. Please contact Elan Technology glass manufacturers for more information. We report on viscosity of a Ge 17 As 18 Se 65 glass over the temperature range of 280420 ☌ and the successful co-extrusion and fiber-drawing of two chalcogenide glass boules to form a core/clad. Elan Technology’s glass ceramic composites also have higher chemical durability, can resist higher temperatures, and can be more easily machined to complex geometries than conventional varieties of glass. In this paper the advantages of using a previously.

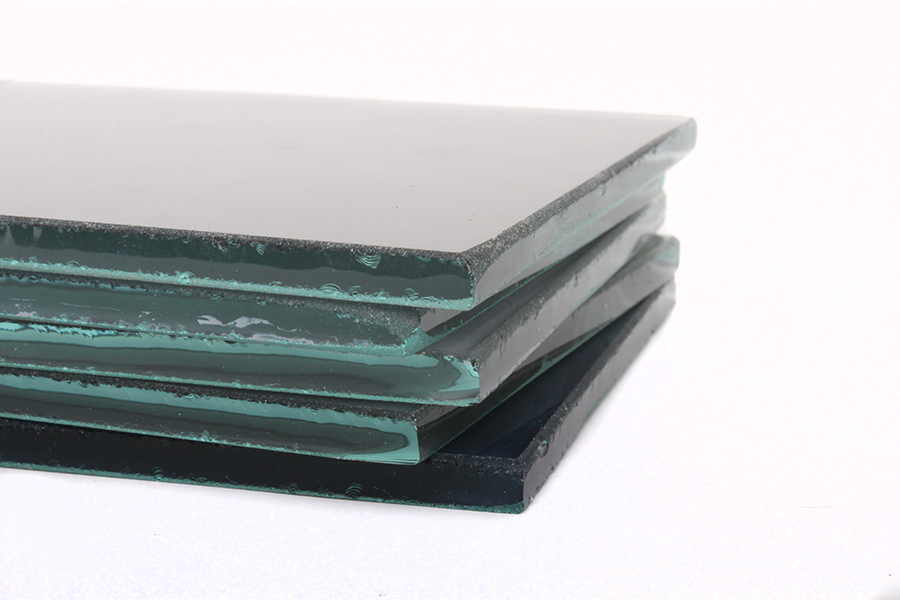

The Elan 46 ceramic glass composite has unique properties that allow for the ability to vary the coefficient of thermal expansion and can therefore form hermetic seals with a variety of metals. Drawing glass from rectangular preforms into thin sheets is one of the manufacturing possibilities. Because glass is extremely strong in compression, compression seals can withstand very high pressures. Compression sealing takes place when the glass and the metal have different coefficients of thermal expansion and the metal shrinks around the solidified glass. Considering the higher permeability of the glass preform, easier impregnation occurs in the middle of hybrid 2 laminate, compared with that of hybrid 1. Used for steel or stainless steel housing, nickel iron pins, and barium alkali glass, compression seals can withstand extremely high pressures and physical stress such as mechanical and thermal shock. Accordingly, glass preform not only decreased the porosity in the hybrid composite, but also maintained a constant void formation along the laminate length. The longest drawn fiber segment with non-detrimental surface defects is 20 m long. Matched seals are used for less intensive applications such as light bulbs and electronic packaging. From the single glass preform, 40 m of 250 m-diameter fiber were drawn with very few surface defects. This “matched seal” is the weaker of the two glass-to-metal hermetic seals and cannot resist large differential pressures across the two materials. When the glass and the metal package have the same coefficient of thermal expansion, the seal derives its strength from the chemical bond between the glass and the oxide formed on the metal parts. There are two types of glass-to-metal hermetic seals which vary based upon the properties of the glass and metals used: Matched Seals "Crystalline Silicon Core Fibres from Aluminium Core Preforms." Nature Communications 6, 6248, DOI:doi:10.1038/ncomms7248, February 2015.Glass Recommendations Glass Preforms for Hermetic Sealing Common Problems in Glass-to-Metal Seal Design Types of Glass-to-Metal Seals Hou, C., Jia, X., Wei, L., Tan, S-C., Zhao, X., Joannopoulos, J.D., Fink, Y. The ability to produce crystalline silicon core fibers out of inexpensive aluminum and glass paves the way for a simple and scalable method of incorporating silicon-based electronics and and photonics into fibers. MIT MRSEC researchers have demonstrated (see figure) that it is possible to fabricate a meter-long crystalline silicon-core, silica-cladded fiber from a preform that does not contain any elemental silicon but rather aluminum and silica (glass).

To date, all thermally drawn fibers are limited to the preform composition and geometry. Traditional fiber-optic drawing involves a thermally mediated geometric scaling where both the fiber materials and their relative positions are identical to those found in the fiber preform. The ability to create fibers from this material would open up exciting vistas for a new generation of fiber-based electronic and optical devices. Crystalline silicon is a critically important electronic material in all consumer electronic products.

0 kommentar(er)

0 kommentar(er)